The Martin-Till Weight Transfer System Re-Distributes Weight from the Center of the Planter to the Wings

Excess weight in the center of a planter or improper weight distribution often leads to yield-robbing compaction, shallow or inconsistent planting, and reduced plant vigor. In addition, the natural reduction in weight that occurs during planting contributes to the problem of down force fluctuations that can negatively impact the accuracy of seed and fertilizer placement. Irregular soil tilth, wet conditions and bumpy or rolling terrain can also wreak havoc with planting accuracy, resulting in uneven emergence and inconsistent stands.

The new Martin-Till Weight Transfer System addresses this weight problem by redistributing excess weight from the center of the planter to the wings. Keeping the wings level and the row units in the ground will keep planting depth consistent through changing conditions.

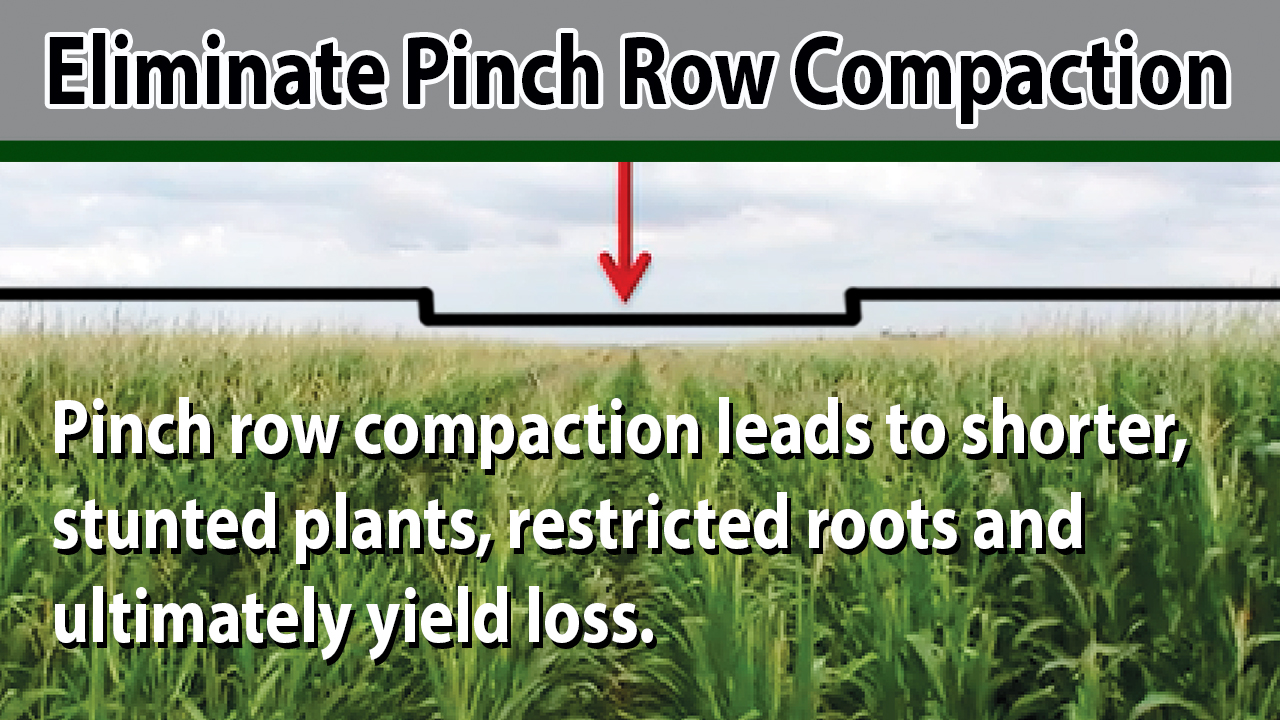

ELIMINATE PINCH ROW COMPACTION

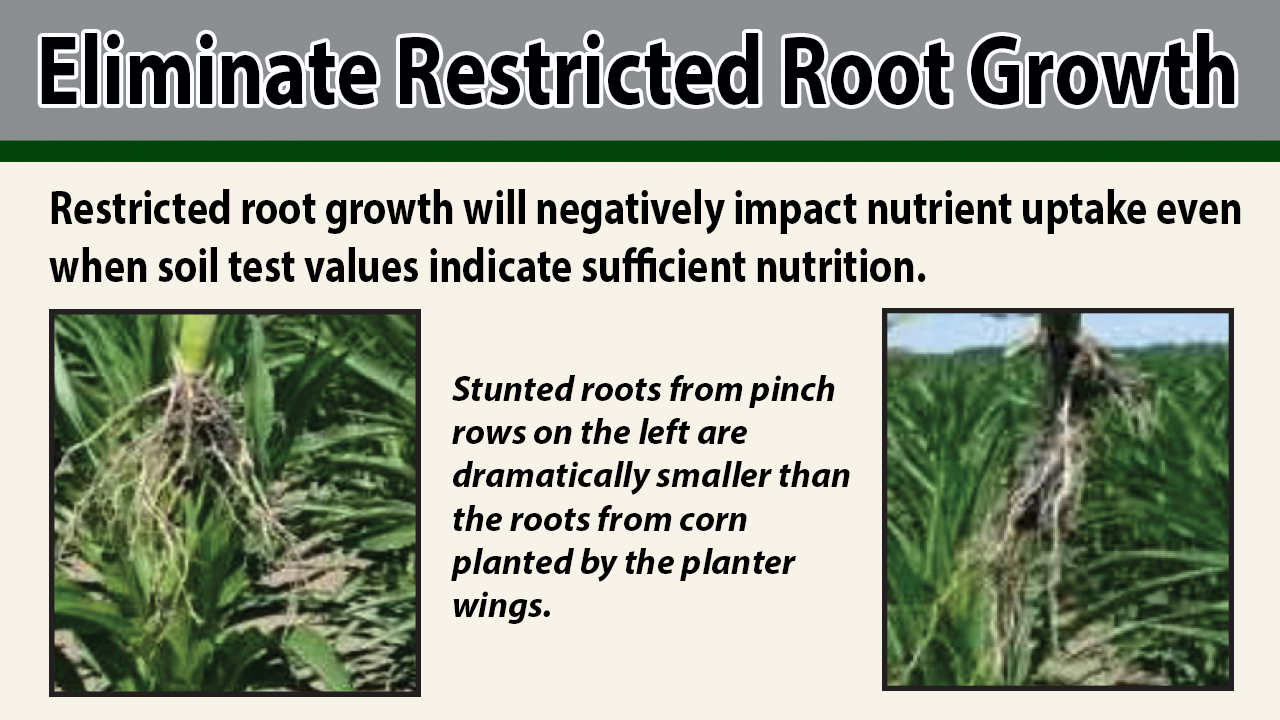

• Pinch row compaction leads to shorter, stunted plants, restricted roots and ultimately yield loss. Pinch-row compaction can have a negative consequence to getting crops off to the right start.

• Issues that can occur due to side-wall compaction include poor germination, non-uniform emergence, limit crop development and restricted root establishment and growth.

• Restricted root growth will negatively impact nutrient uptake even when soil test values indicate sufficient nutrition.

VIDEO: The Martin Weight Transfer System - Benefits Explained and In Action

• In-Cab Control Box—Allows for easy adjustment as you plant

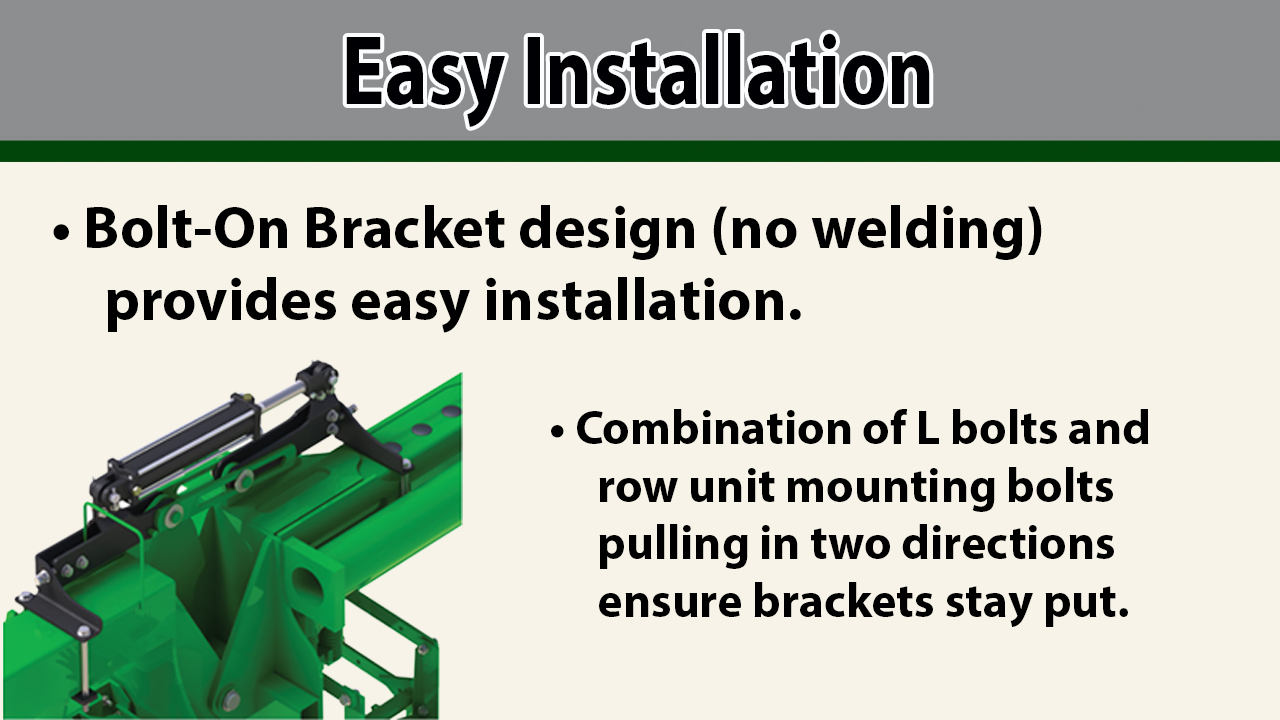

• Bolt-On Bracket design (no welding) provides easy installation

• Interlocking tab and slot design fit together to transfer load to the tool bar

|

|

|