MAY WES POLY SKID SHOES

PROBLEM: Soil and debris builds up on the under-side of the combine head, causing pushing and piling of soil.

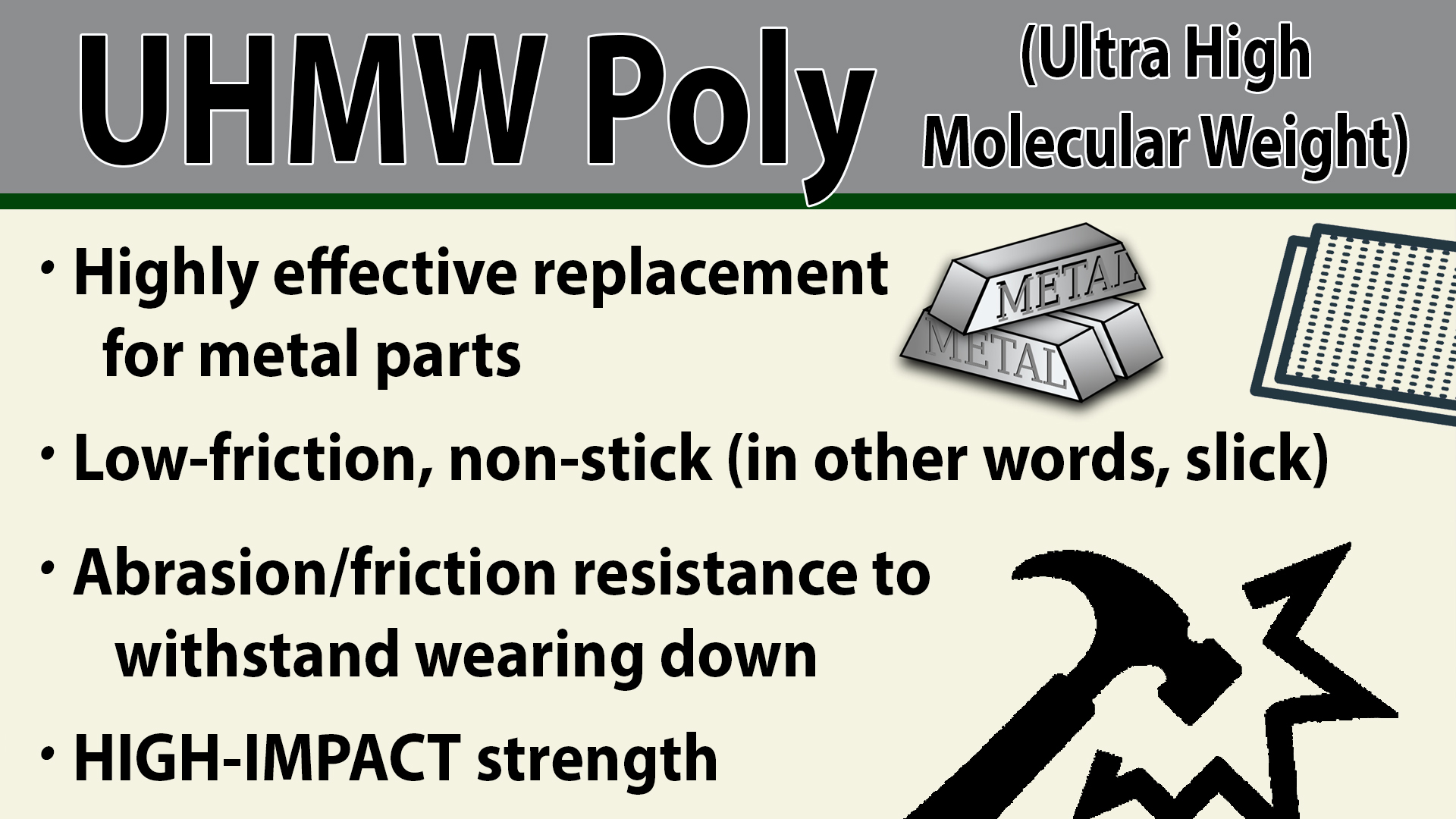

SOLUTION: The smooth, slick surface of the May Wes Poly Skid Shoes allow you to run your head and cutterbar down as low as possible, leaving little to no crop in the field.

-----------------------------------------------------------------------------------

Run your head closer to the ground without pushing and piling soil and you will put more crop in the combine even in wet sticky conditions.

The smooth, slick surface of the May Wes Poly Skid Shoes allows you to run your head and cutter bar down as low as possible, leaving little to no crop in the field - MORE CROP IN THE COMBINE.

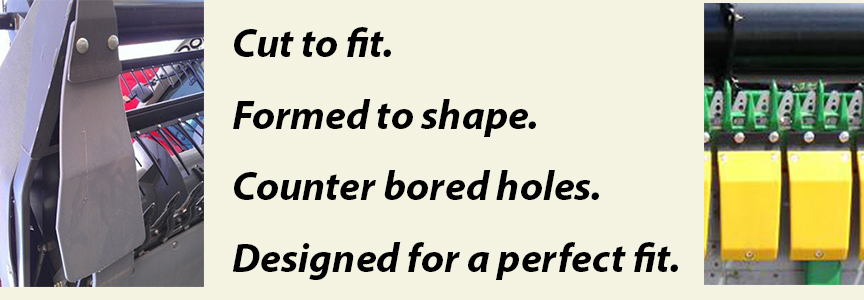

• Machine cut from solid sheets of solid virgin UHMW poly and formed to fit your head

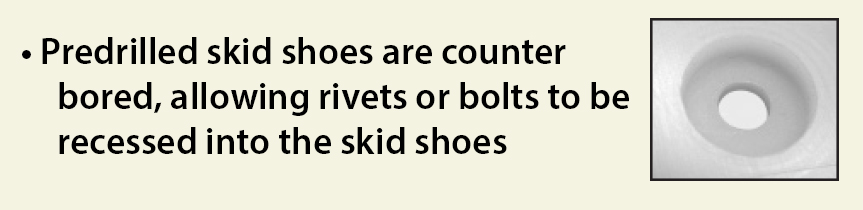

• Predrilled skid shoes are counter bored, allowing rivets or bolts to be recessed into the skid shoes

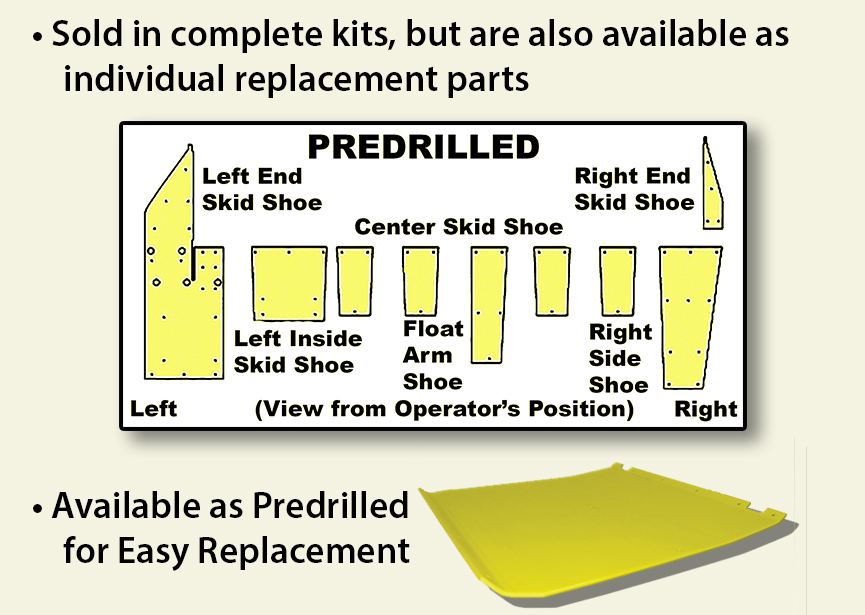

• Sold in complete kits, but are also available as individual replacement parts

PREDRILLED AND UNDRILLED FOR EASY REPLACEMENT

Machine cut from solid sheets of UHMW Poly and formed to fit your head, these Poly Skid Shoes are available predrilled or undrilled.

PREDRILLED. Computerized drilling of counterbored holes makes them with .01" of factory drilled holes, making replacement easy and saving hours of labor compared to undrilled skid shoes. Counterboring holes allow for rivets or bolts to be recessed into skid shoes,keeping soil from building up on bolts or rivets.

UNDRILLED. Choose undrilled skid shoes when you need to match holes already drilled in metal shoes. For accuracy in drilling new poly skid shoes to match previous holes drilled, just position new shoes on factory metal shoe. Shine a light from behind the drilled metal shoe through white poly skid shoe. The light will shine through the hole, providing a marker for the placement of the new hole.

-