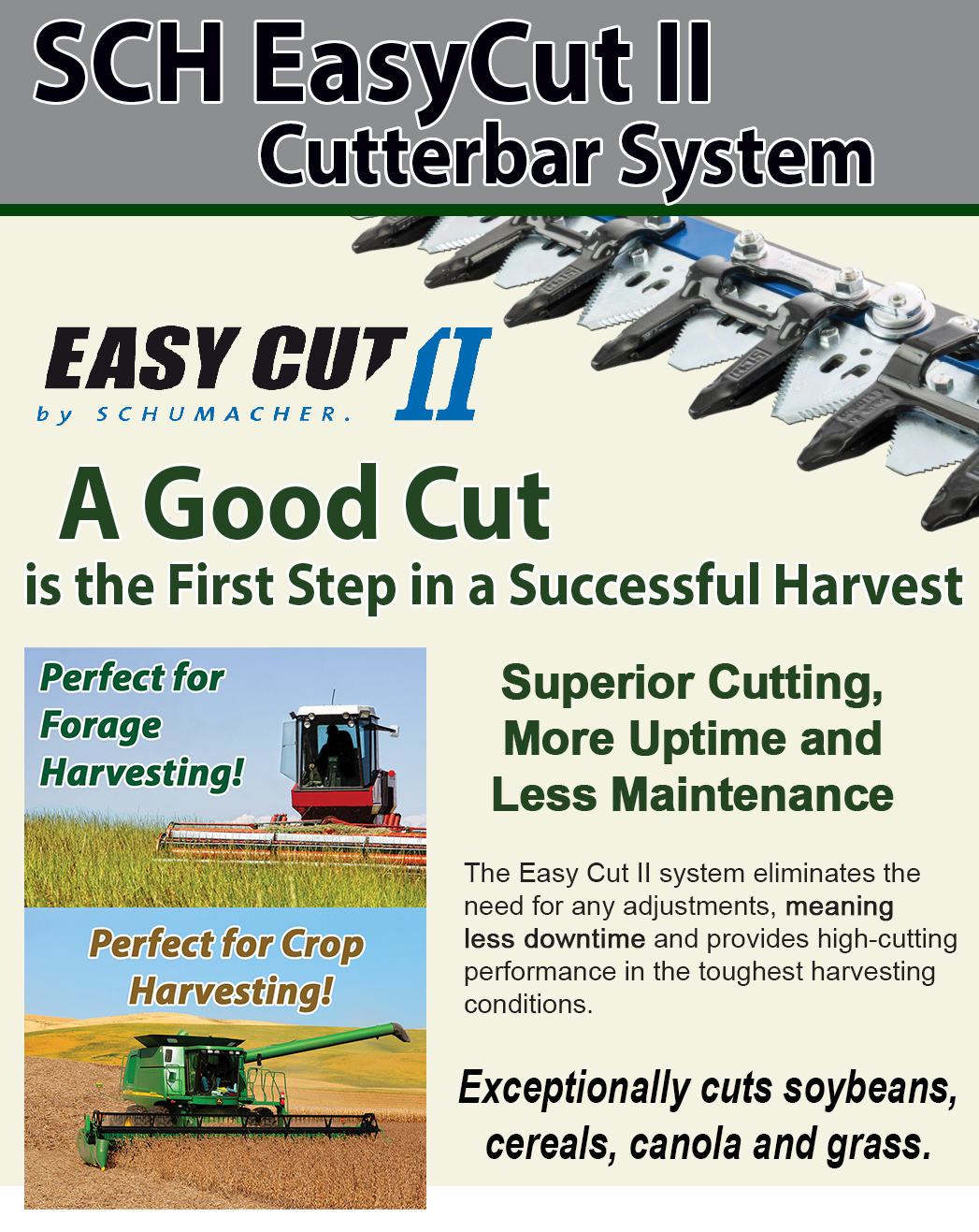

SCH EASYCUT II CUTTERBAR SYSTEM

Superior Cutting, More Uptime, and Less Maintenance

The EasyCut II system eliminates the need for any adjustments, meaning less downtime and provides high-cutting performance in the toughest conditions. High quality spring steel guards, completely hardened sections and roller guides give this sickle bar system durability and low maintenance.

The SCH Easy Cut II Conversion Kit is a universal cutting system that fits most combines, windrowers, mower conditioners and mowers. With the use of spring steel guards, completely hardened sections and rollers, the Easy Cut II cutting system combines high quality and wear-resistant components to provide the most innovative knife system in the market today. The Easy Cut II system eliminates the need for any adjustments, meaning more uptime and less maintenance. SCH has specially designed each part to be universal. By doing so, each of the common components can be used on many different applications. The SCH Easy Cut II system provides high-cutting performance even in extreme harvesting conditions. Most platforms on the market today can be updated to the SCH Easy Cut II Conversion Kit.

- No Adjustments - With the enclosed design of the guards, hold downs are eliminated, along with all the adjustments that come with them

- Choices to Suit Every Harvest Condition - Roller guides or wear plates; short or long guards; course or fine tooth sickle sections

- Easy Handling - Most conversion kits and sectional knife assemblies can be shipped as a small parcel carrier

Exceptionally cuts soybeans, cereals, canola, legumes & grass

-------------------------------------------------------------------------------------------------------------------------------------------------------------------

It All Starts Here: The Cutting System is the first part to touch your crop.

Despite all technological advances around the combine and platform, the cutting system is still the first part to touch your crop and determines your harvest success. The Schumacher cutting system is an essential component for successful combining and supports maximum performance of combine harvesters.

-

The SCH Easy Cut II Cutterbar Conversion Kit is a universal cutting system that can be used in any type of crop. With the use of spring steel guards, roller guides, and completely hardened sections, the Easy Cut II cutting system combines high quality and wear-resistant components to provide the most innovative knife system in the market today. The Easy Cut II system eliminates the need for any adjustments, meaning more uptime and less maintenance.

S.I. Distributing has over 33 years of experience in selling Schumacher products.

MORE ADVANTAGES:

• EasyCut II blunt guard eliminates spearing of residue

• EasyCut II guard gets more crop through the cutting system

• SCH knife system never needs adjustment

• SCH guards bolt to top and bottom of platform

• SCH guards are fully heat treated

• SCH guards have two beveled cutting edges

• SCH sections are fully heat treated

• SCH sections will not bend

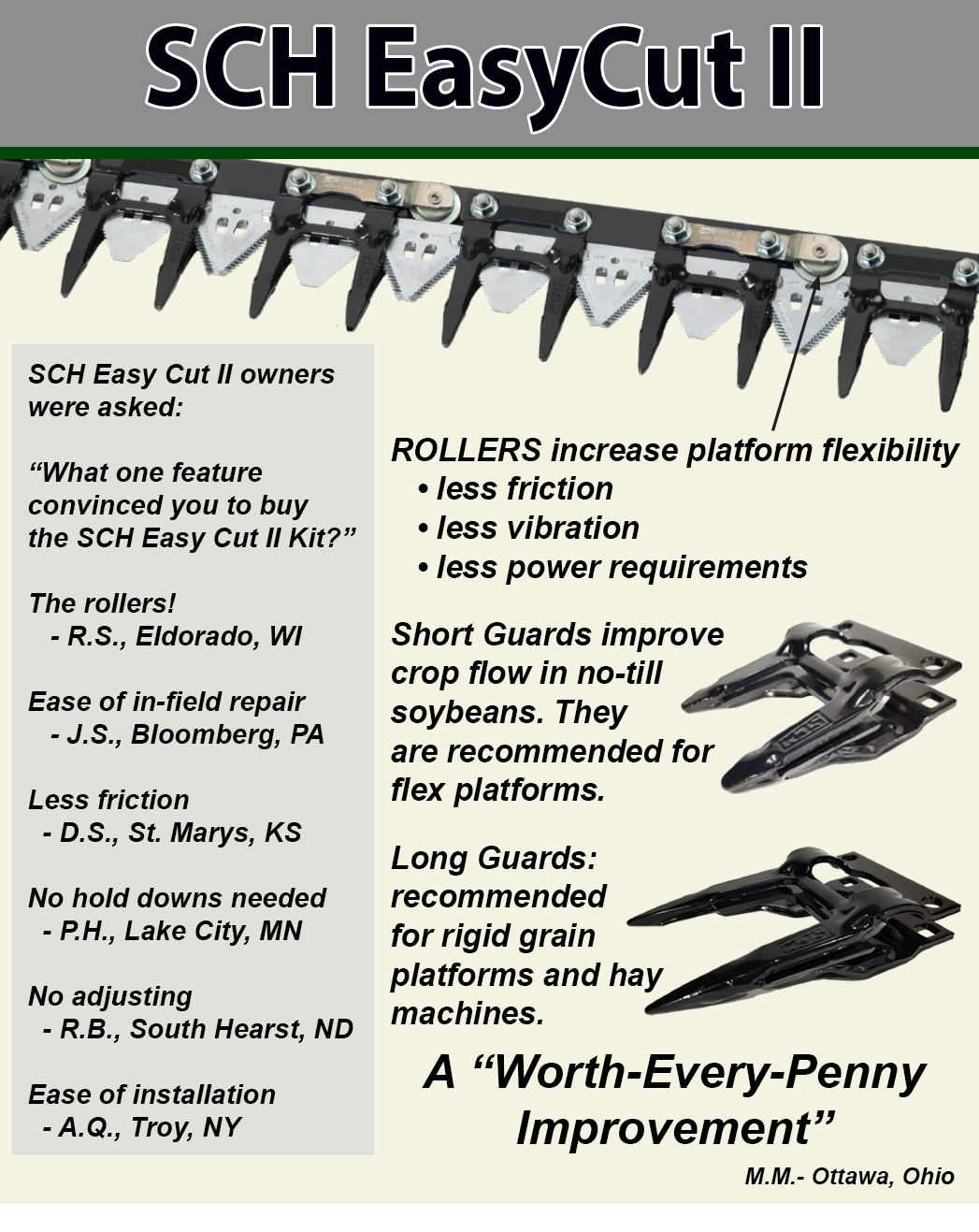

• Optional SCH rollers improve performance

• Optional SCH rollers reduce friction & vibration

IMPROVEMENTS

The SCH top and bottom roller guides allow more flexibility on the platform while decreasing the likelihood of material buildup around the rollers.

As before, they continue to reduce the friction on the knifeback and allows the knife to run more smoothly. It also results in less knife load and power requirements for the knife drive or wobble box.

The short SCH EasyCut guards improve crop flow in no-till soybeans. They are recommended for flex grain platforms.

|

|

|

|