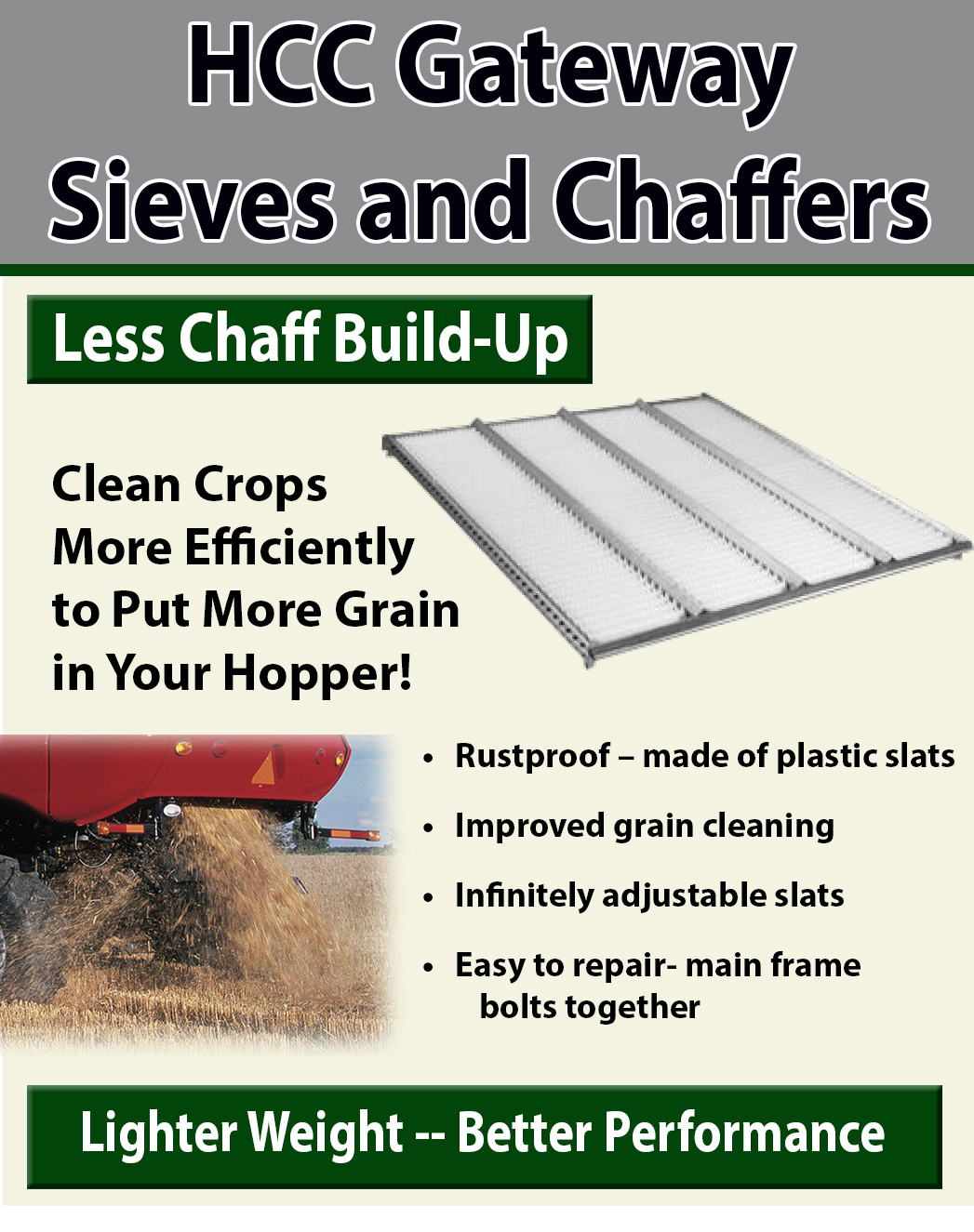

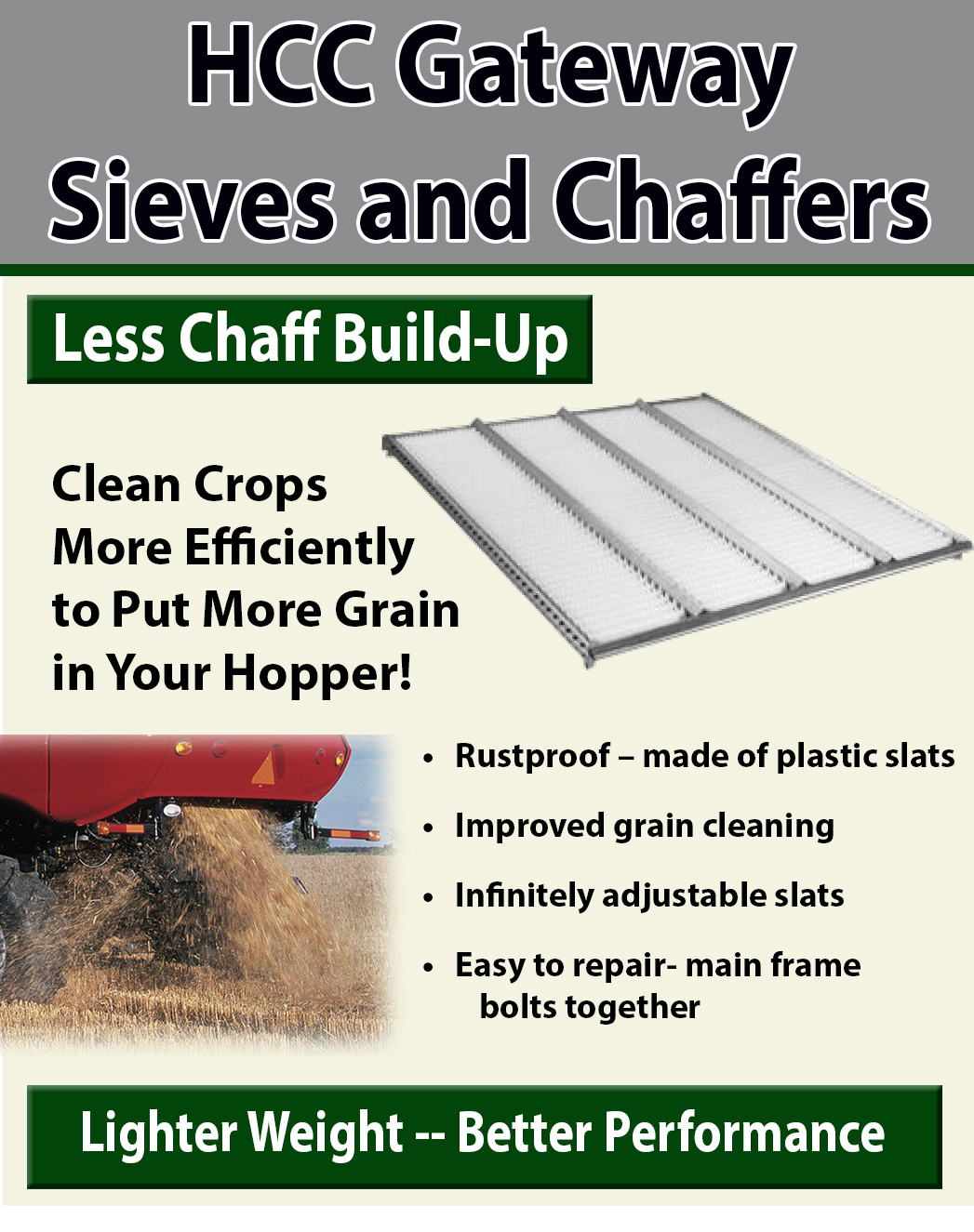

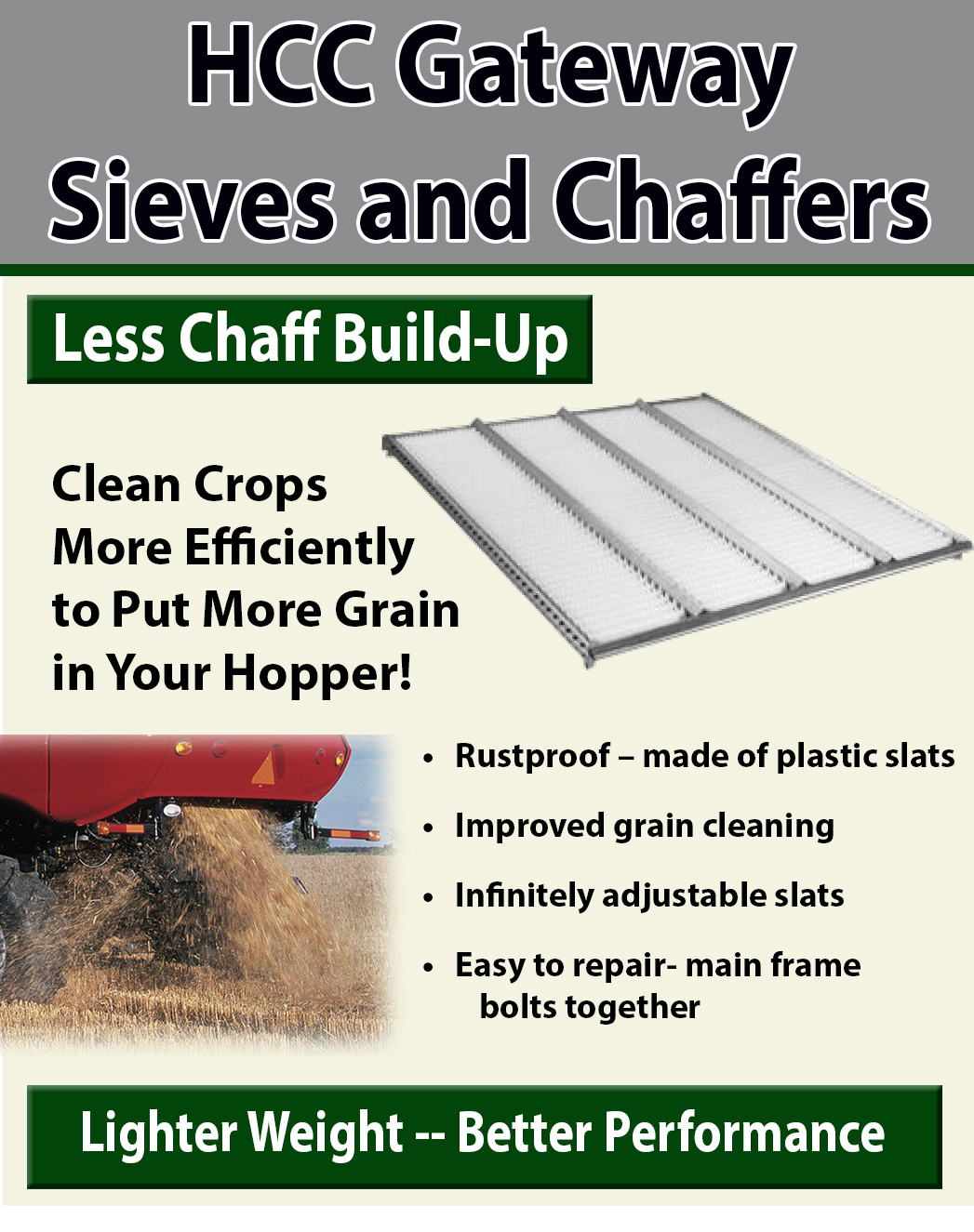

Gateway™ Sieves & Chaffers

Gateway™ Sieves & Chaffers offer a number of advantages over standard steel sieves and chaffers including:

• Lightweight – up to 50% lighter

• Rustproof – made of plastic slats

• Less chaff build-up

• Improved grain cleaning

• Infinitely adjustable slats

• Easy to repair- main frame bolts together

The Gateway, HCC's sieve and chaffer system, is significantly lighter than standard sieves and chaffers found on current combines. The patented design utilizes aluminum and plastic construction for lower frame weight. That reduces wear and tear on cleaning shoe combine downtime.

Unlike conventional all-steel sieves and chaffers that are difficult or impossible to repair, the modular construction of Gateway Sieves & Chaffers permits easy and cost-effective repair. The added lubricity of the plastic slats also prevents crop build up on the slats, especially when harvesting in near-freezing conditions.

Side-by-side field comparisons demonstrate that Gateway Sieves & Chaffers clean grain as well or better than current systems. Gateway Sieves excel in cleaning lighter crops (like alfalfa seed) and heavy crops (like high yield / high moisture corn).

Gateway Sieves & Chaffers have been tested and refined over several harvest seasons by high-hour combine users.

Gateway Sieves & Chaffers are manufactured by HCC, Inc., the same company that makes virtually all of the original equipment sieves and chaffers. As a result, fit and function is guaranteed to meet or exceed original equipment standards. Gateway works with manual or remote adjustment systems.

Why two spacing options?

Narrow Spacing (33mm): Used for small grains: wheat, alfalfa, and cereal grains; 33ST top 33ST bottom.

Wide Spacing (45mm): Used for large crops: corn and soybeans; provides faster operation through high-yielding crop; 45LT top 33ST bottom.