---------

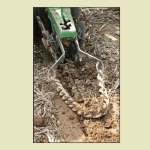

The Martin-Till 2024 Product Line Focus can be summed up in seven words - CLEAR, CONTROL, FERTILIZE, TRANSFER, CLOSE. SEAL AND LEVEL!

And in nine products - Martin-Till floating row cleaners, Smart Clean row cleaner adjustment system, the Weight Transfer System, Unit Mounted Fertilizer Openers (UMOs), Closing Wheels for Planters (including the fCrusher Closing Wheel), the 2nd Stage Closer, the fCrumbler and the Twisted Drag Chain Kits

Martin-Till planter attachments make it possible for you to plant into higher levels of residue and moisture.

Higher levels of mulch mean less erosion and more consistent and lower cost yiels, all while the soil is rebuilding itself.

VIDEO: MARTIN-TILL PLANTING ATTACHMENTS PRODUCT SPOTLIGHTS - BENEFITS EXPLAINED AND IN ACTION, with footage of the 2nd Stage Closer, fCrusher Closing Wheel and the fCrumbler in action.

|

|

|

|

|

|

|

|