PPS FLANGE BUSHING PARALLEL LINKAGE ARM KITS

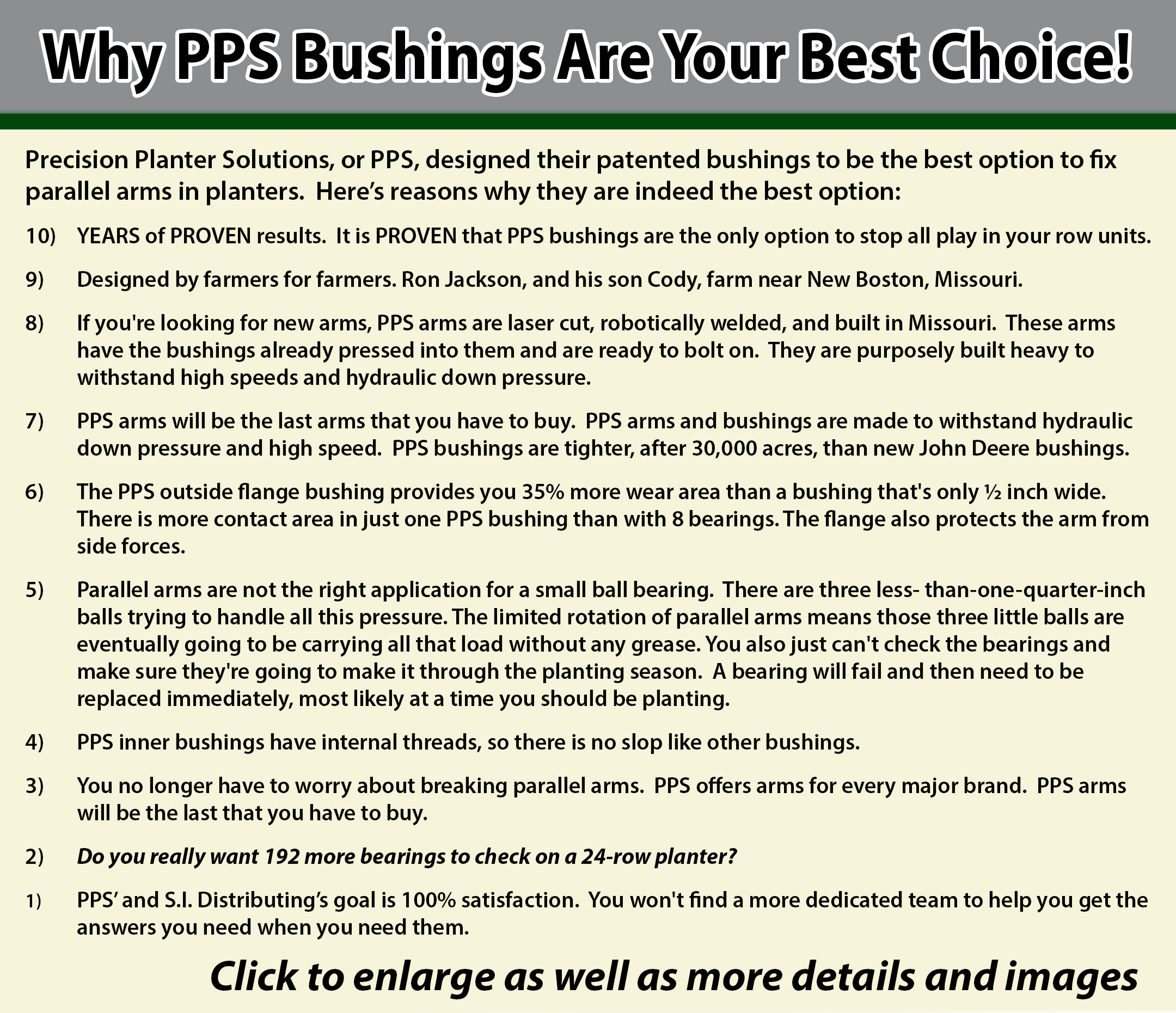

It doesn’t matter if you are wanting to fix your existing arms, or buy new ones, it all starts with the patented bushings from Precision Planter Solutions, or PPS. In the last several years, many farmers have upgraded to hydraulic down force and high speed on their planters, which requires more down pressure to keep the row unit at the intended depth. This has been hard on parallel arms.

Many farmers started with fairly tight row units when adding their hydraulic down pressure, only to find the following Spring, when going over their planters, that there was an excessive wear on their parallel arms.

It just doesn't make sense to have thousands of dollars’ worth of precision upgrades on a row unit that moves and shakes in every direction. PPS has created a system that would take this abuse, give you years of trouble-free service and be easy to replace when you felt it was needed.

CLICK for more details and images regarding "Why PPS Bushings are Your Best Choice"

VIDEO "Are You Deciding What to Do with Your Parallel Arms?"

In this video, Ron Jackson, owner of Precision Planter Solutions/PPS, with his daughter Casey, highlight the PPS Rebuild Kits including the advantages and comparisons to other parallel arms.

Three Choices:

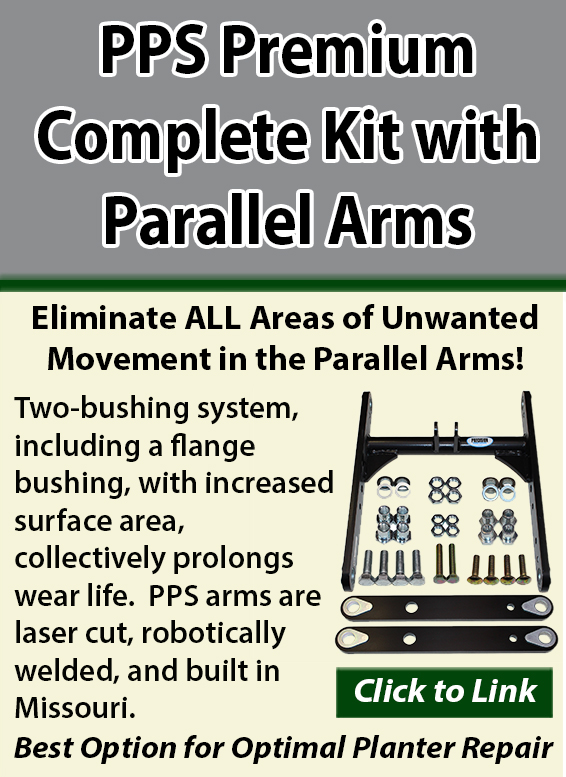

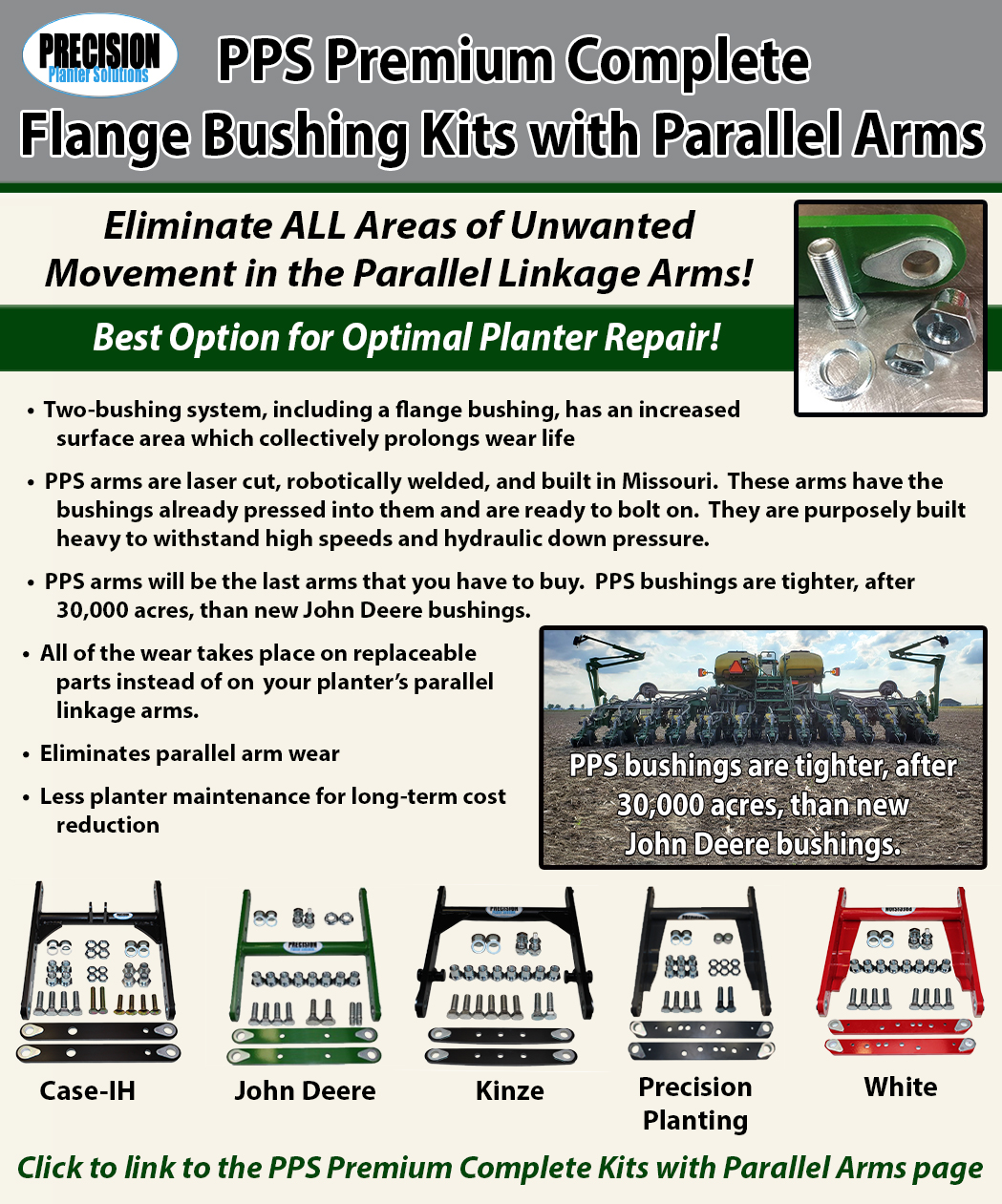

PPS PREMIUM COMPLETE BUSHING KITS WITH PARALLEL ARMS

To ensure OPTIMAL fit, especially where worn support plate and row unit holes are prevalent, premium arm kits include 11/16” shouldered 5/8” bolts as part of the hardware package. You will need an 11/16” reamer to enlarge the planter support plate and row unit.

Click for the PPS PREMIUM COMPLETE FLANGE BUSHING KITS WITH PARALLEL ARMS page

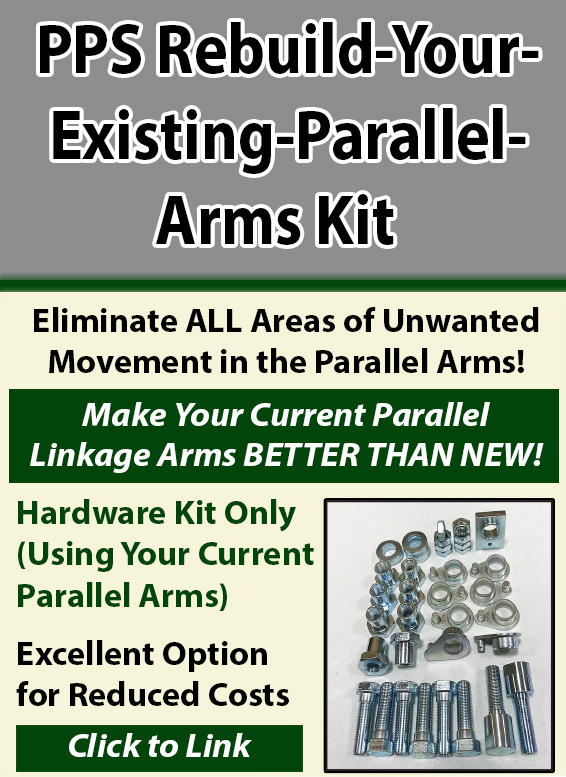

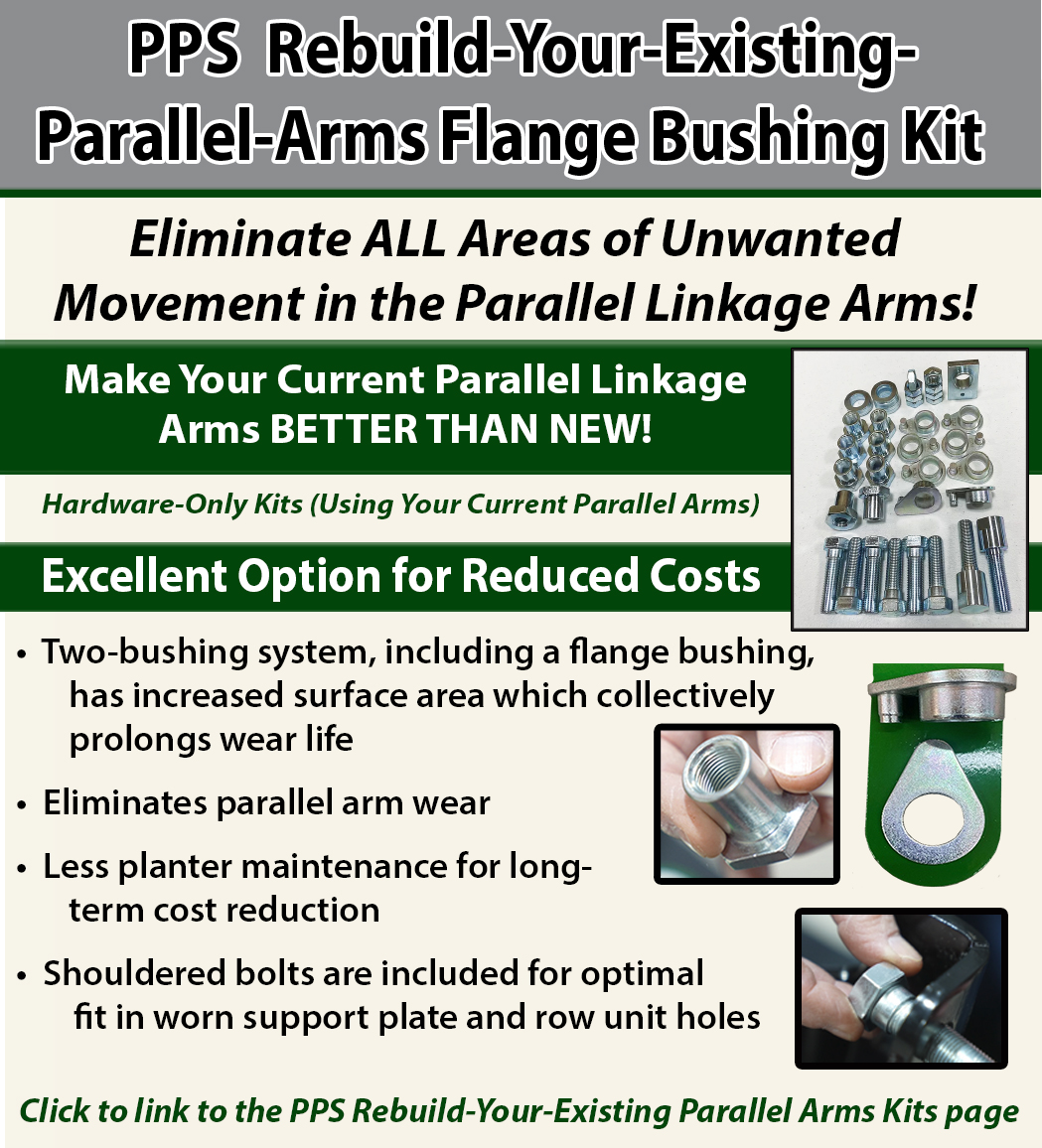

PPS REBUILD-YOUR-EXISTING PARALLEL ARMS REBUILD KITS

Click for the PPS REBUILD-YOUR EXISTING-PARALLEL-ARM FLANGE BUSHING (HARDWARE ONLY) KITS page

PPS NO-REAM COMPLETE KITS WITH PARALLEL ARMS

This option is available for customers who prefer not to ream the support plate and row unit holes. These rebuild kits come with flange-bushing -installed parallel arms and shoulder-less bolts. No reamers are needed for these kits.

They are ideal for narrow row planters and econo-fold planters where clearance around support plates is exceptionally tight.

NOTE: The PPS No-Ream Complete Kits do not eliminate all areas of unwanted movement in the parallel arms.

Click for the PPS NO-REAM COMPLETE FLANGE BUSHING KITS WITH PARALLEL ARMS page

|

|

|

|

|

|